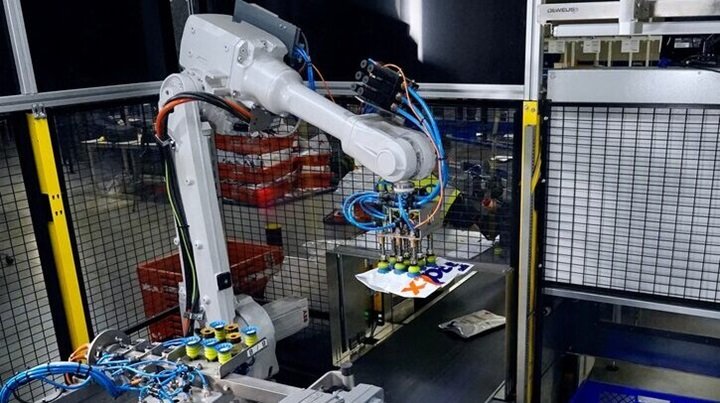

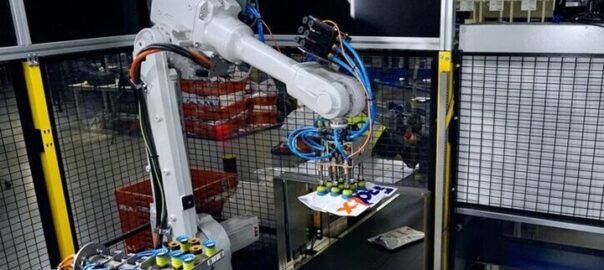

FedEx improves operational processes with AI-powered robotic sorting arm

FedEx has introduced an AI-powered sorting robot at its air network location in Cologne, Germany, to assist staff with the sorting process and allow them to focus on more complex tasks.

The robot is the first of its kind in the European FedEx network and will be used to sort documents and smaller parcels up to 4kg, processing up to 1,000 pieces per hour and managing around 90 destinations simultaneously.

“AI-supported technologies like this help us manage shipments more effectively, enhance customer experience and boost our competitive edge as e-commerce continues to drive growth in the market,” said Boris Stoffer, managing director of network operations Germany at FedEx. “These technologies are also supporting our employees by reducing physical strain by taking over repetitive, high-volume tasks.”

The robotic arm is part of FedEx’s wider goal of developing a smart logistics network. In 2020, the company installed four robotic arms to automate small package sorting at its Memphis Hub in Tennessee. In 2022, it deployed sorting robots in its South China E-Commerce Shipment Sorting Center in Guangzhou and its Singapore Hub. The company also uses robotic product sortation and identification systems at 17 US sorting facilities, including New York, Las Vegas and Ohio.

“This robotic in-feeding system is proof of our commitment to innovation,” said Georgiana Constantin, manager of planning and engineering innovation and properties design at FedEx. “Delivering best-in-class service is our ambition, driven by a passion for innovation that puts our customers first.”

Author Credits- HAZEL KING

Parcel and postal technology INTERNATIONAL